Choosing the right vacuum tube lifter depends on several factors, including the type and weight of the objects to be lifted, the available workspace, and the specific lifting requirements.

Firstly, it’s important to consider the weight and size of the objects to be lifted.

As this will determine the lifting capacity of the vacuum tube lifter. For lighter loads, the Vacugrip model may be suitable, while the Jumbo model is more appropriate for heavier loads.

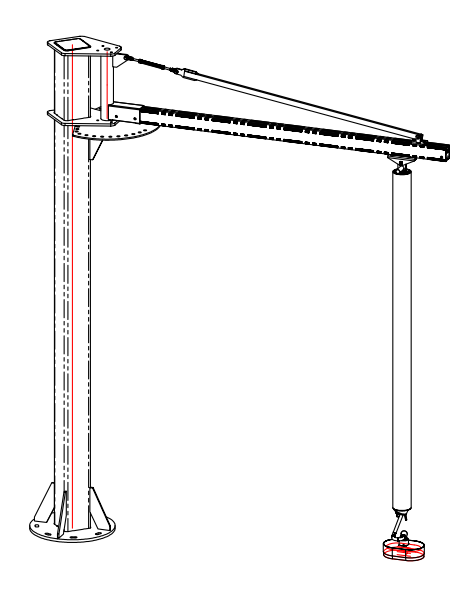

Next, consider the available workspace and the specific lifting requirements.

This includes the minimum working space/radius and plant height of the workshop, as well as the subgrade situation. Additionally, consider the maximum stack height and transportation distance that the vacuum tube lifter will be required to handle.

Finally, it’s important to consider any additional features or operation modes that may be required for the specific lifting tasks.

For example, if the operator needs to move the lifted objects over long distances, a pull-type handle control may be more suitable, while a two-handed grip may be better for more precise lifting and placement.

By carefully considering these factors, you can choose the right vacuum tube lifter for your specific needs and ensure efficient and safe lifting operations.

Customer Cases

- SPC of working pieces to lift:

Job1: PE bag 25kg;

Conception:

1, Application: To handling bag or carton from to one pallet 100mm to the other and stacking up 1800mm max.

2, Move from left to right in about 3.5M, up and down in 1700mm.

3, Working radius: around 180 degrees rotation by angle limitation.

4, Ceiling height: over 4 meters

5, Maximum weight: 30 Kg

6,Power Supply: 380V/50Hz/3Ph

Main Parameter and Components

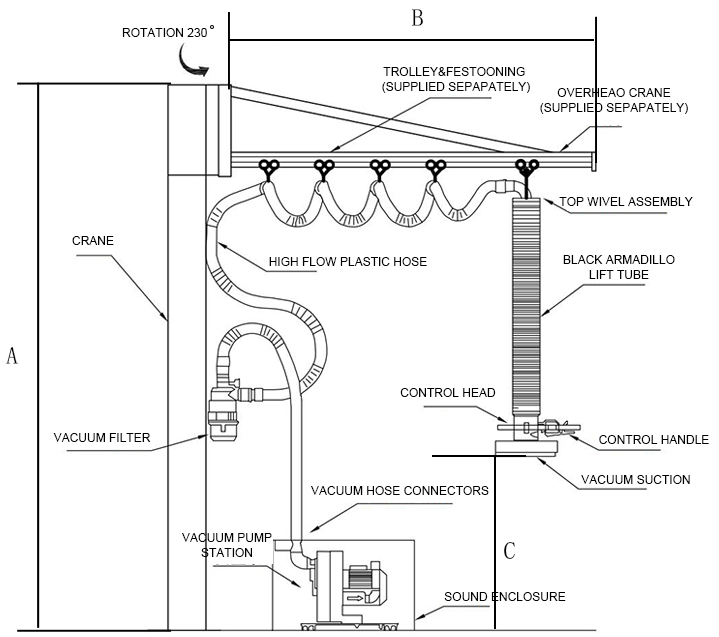

The vacuum tube lifter consists of several components including universal swivel heads, a vacuum tube, valve controller, suction pads, vacuum blower, vacuum pipe, air filter, soundproof box, and electrical box with accessories. The universal swivel heads allow for easy handling of various objects, while the vacuum tube creates suction to lift and move the objects. The valve controller regulates the vacuum flow and release, and the suction pads securely hold the objects in place. The vacuum blower creates the suction power, and the vacuum pipe connects all the components together. An air filter ensures clean air is used in the suction process, and a soundproof box reduces noise. An electrical box and accessories are also included for power and control.

Universal Swivel Heads:

These are the components that come into direct contact with the objects being lifted. The swivel heads are designed to fit a variety of shapes and sizes, and they rotate 360 degrees, providing flexibility and ease of use.

Vacuum Tube:

The vacuum tube is the main component of the lifter that creates suction power to lift and move the objects. The tube is made of a durable material and is designed to withstand heavy use.

Valve Controller:

The valve controller regulates the flow of air in and out of the suction pads. This ensures that the objects being lifted are held securely in place and released smoothly when necessary.

Suction Pads:

Suction pads are attached to the universal swivel heads and are responsible for creating a vacuum seal between the lifter and the object being lifted. The pads are made of a soft, flexible material that conforms to the shape of the object, ensuring a strong hold.

Vacuum Blower:

The vacuum blower creates the suction power that is transmitted through the vacuum tube and into the suction pads. It is a powerful motor that creates a high volume of air flow, generating a strong vacuum force.

Vacuum Pipe:

The vacuum pipe connects all the components of the lifter, including the suction pads, the vacuum blower, and the valve controller. It is a flexible pipe that is designed to withstand heavy use and can be easily replaced if necessary.

Air Filter:

The air filter ensures that the air used in the suction process is clean and free from impurities. It prevents dust and debris from entering the lifter, which can cause damage to the components and affect the quality of the suction power.

Sound Proof Box: The soundproof box is an optional component that reduces the noise generated by the vacuum blower. It is especially useful in environments where noise levels need to be kept low, such as in a production or manufacturing facility.

Electrical Box and Accessories:

The electrical box contains the necessary components for powering and controlling the lifter, including a power switch, a control panel, and electrical wiring. The accessories include cables, connectors, and other components that are necessary for proper installation and use of the lifter.